Dodaj produkty podając kody

Mapowanie systemu TraceTek

Mapowanie systemu TraceTek Leak Detection System polega na stworzeniu mapy instalacji i zawiera odniesienia między odległościami przewodów sensorowych i czujników punktowych (w stopach lub metrach) a fizycznymi odniesieniami w zainstalowanej aplikacji w budynku.

Mapa systemu stosowana jest razem z panelami alarmowymi które posiadają opcję lokalizacji wycieku +/- 1 metr przewodu sensorowego.

1. Zacznij od kopii roboczej planu piętra budynku lub rysunku układu rur, który pokazuje, gdzie został zainstalowany przewód sensorowy. Prosty system może mieć tylko jeden obwód, bardziej złożona instalacja może mieć wiele pojedynczych obwodów.

2. Wybierz dowolny obwód i zlokalizuj część obwodu najbliżej urządzenia monitorującego.

3. Zasymuluj wyciek za pomocą jednej z nst. metod:

Mapowanie przewodu sensorowego TT1000, TT3000

W przypadku przewodu sensorowego TT1000 lub TT3000 zdecydowanie zaleca się użycie TT-MAP-TOOL narzędzia do mapowania. Wsuń szczotkę na przewód sensorowy i pozostaw na miejscu przez co najmniej dziesięć sekund. Można również użyć wilgotnej szmatki, ważne jest, aby przewód sensorowy był suchy w każdym punkcie mapowania przed przejściem do następnego, aby zapobiec fałszywym odczytom i/alarmom serwisowym. Nie używaj chusteczki, ponieważ może to pozostawić wilgotne osady na przewodzie pomiarowym. Testy TT1100-OHP można wykonać za pomocą nasadki mapującej (TT-MAPPING-CAP-PC) na końcu każdego odcinka kabla czujnikowego.

Mapowanie przewodu sensorowego TT5000, TT5001

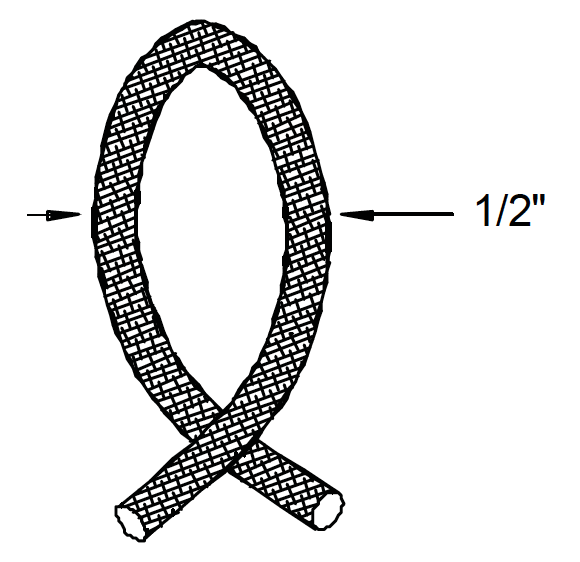

Proces mapowania dla TT5000 i TT5001 jest podobny do powyższego procesu, z wyjątkiem tego, że wyciek można zasymulować przez zgięcie przewodu sensorowego w małym promieniu, jak pokazano na grafice. Pamiętaj, aby utrzymać „wyciek” (zagięcie) przez co najmniej dziesięć sekund. Nie używaj węglowodorów do testowania/mapowania TT5000, ponieważ ten przewód jest przeznaczony do jednorazowego użytku. Aby uzyskać więcej informacji, zapoznaj się z odpowiednią kartą danych.

Mapowanie terminalem TT-MAPPING-CAP

TT-MAPPING-CAP jest to terminal zakończeniowy symulujący wyciek, używany do mapowania przewodów sensorowych.

Dostępny w wersji:

- TT-MAPPING-CAP-PC Używany do mapowania przewodów sensorowych TT1000, TT3000, złącze PC.

- TT-MAPPING-CAP-MC Używany do mapowania przewodów sensorowych TT500, TT5001, TT7000, złącze MC.

W przypadku większych systemów, TT-MAPPING-CAP należy montować sekwencyjnie do każdego dostępnego złącza. Terminal mapujący symuluje wyciek w miejscu, w którym jest zainstalowany.

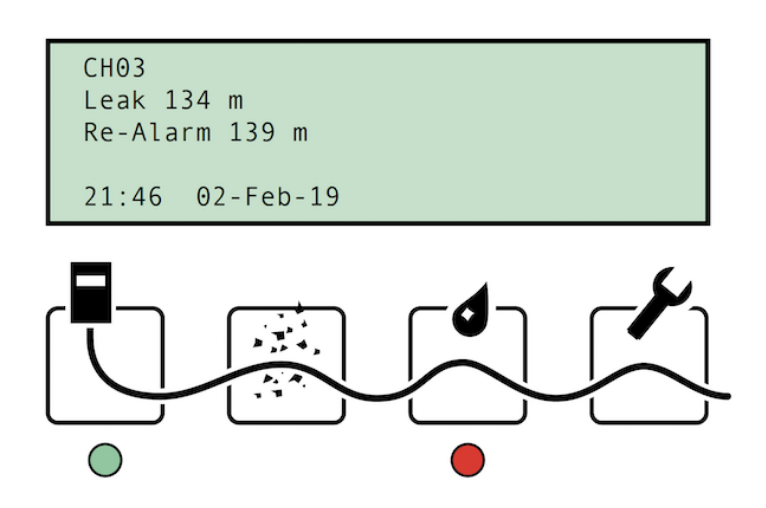

Odczytanie zasymulowanego wycieku

Na panelu alarmowym odczytaj wyświetloną odległość dla lokalizacji „wycieku”. Zapisz tę odległość na kopii roboczej rysunku systemowego. Po zapisaniu lokalizacji wycieku na rysunku systemowym przejdź do lokalizacji znajdującej się dalej w systemie i powtórz proces. Znaczniki mapujące TT-TAG i odczyty odległości są wymagane co 4 - 5 metrów. Wybierz lokalizacje w rogach pomieszczenia, przed centralami wentylacyjnymi, przy słupach konstrukcyjnych lub innych „znacznikach terenu”, które prawdopodobnie nie ulegną zmianie, nawet jeśli w przyszłości zmieni się wyposażenie budynku. Należy pamiętać, że w przypadku wykrycia prawdziwego wycieku operator użyje „mapy systemu”, aby znaleźć fizyczną lokalizację wycieku na podstawie odległości lokalizacji wycieku zgłoszonej na panelu alarmowym.

4. Powtórz powyższe procesy dla każdego obwodu czujnika w systemie.

Mapowanie dla dwóch osób lub dla jednej osoby

Jeśli dostępne są dwie osoby, zdobądź zestaw dwukierunkowych radiotelefonów i umieść jedną osobę przy panelu alarmowym. Druga osoba idzie po zainstalowanym systemie z rysunkiem systemu w ręku. Obserwator panelu odczytuje i zgłasza lokalizację symulacji wycieków. Operator wycieków może wtedy natychmiast zapisać odległość na rysunku i przejść do następnej lokalizacji mapowania.

Jeśli system TraceTek jest zarządzany przez centralę alarmową TTDM-128, TS-12, AT-APA (centrale te posiadają historię zdarzeń), to pojedynczy operator może dość łatwo wydajnie uzyskać dane mapowania. Oto jak:

- Najpierw zsynchronizuj godzinę na panelu z zegarkiem operatora.

- W centrali alarmowej TTDM-128 tymczasowo włącz funkcję automatycznego resetowania. (Menu | Konfiguracja nieszczelności | Automatyczne resetowanie | WŁ.).

- Symuluj wycieki za pomocą narzędzia mapującego (TT1000, TT3000), zginając kabel (TT5000, TT5001) lub używając terminala mapującego. Zamiast odnotowywać lokalizację wycieku na rysunku roboczym, zaznacz czas mapowania każdej lokalizacji. (Spróbuj odczekać około dwóch minut między lokalizacjami mapowania).

- Kiedy wszystkie odpowiednie lokalizacje zostaną zmapowane, wróć do panelu alarmowego i spójrz na historię zdarzeń. Przechodząc wstecz przez zarejestrowane zdarzenia, będziesz mógł zobaczyć wygenerowaną lokalizację wycieku i czas wykrycia każdego wycieku. Przepisz lokalizacje wycieków do rysunku układu.

- Pamiętaj, aby przywrócić funkcję automatycznego resetowania do WYŁ.

Przygotowanie mapy końcowej

Gotowe mapy są zazwyczaj przygotowywane przy użyciu programu AutoCAD i są uproszczonym planem piętra lub schematem rur przedstawiającym

- podstawowe cechy fizyczne budynku lub systemu,

- przybliżoną lokalizację zainstalowanego przewodu sensorowego,

- lokalizację centrali alarmowej oraz odczyty lokalizacji uzyskane podczas proces mapowania. Zalecane są co 4 - 5 metrów.

Jeśli to możliwe, użyj kolorów. Wszystkie lokalizacje złączy przewodów powinny być oznaczone, aby ułatwić przyszłą wymianę przewodów. Celem jest zapewnienie przyszłemu operatorowi wystarczającej ilości informacji, aby znaleźć wyciek na podstawie informacji o lokalizacji wyświetlanych na panelu alarmowym. Szczegółowość powinna być wystarczająca, aby szybko i jednoznacznie znaleźć wyciek, bez zbytniego zaśmiecania gotowego produktu. Drukowane mapy są często laminowane lub oprawiane w ramki i zawieszane na ścianie obok panelu alarmowego. Gdy dostępne są bardziej rozbudowane systemy sterowania budynkiem, mapa jest często importowana do graficznego interfejsu użytkownika, aby w razie potrzeby uzyskać łatwy dostęp on-line.

Przykłady punktów mapy

Znaczniki TT-TAG na przewodzie sensorowym TT1000

Znaczniki TT-TAG na przewodzie sensorowym TT1100-OHP:

Znaczniki wykonane na potrzeby aplikacji przez naszego instalatora:

Naklejki wykonane na potrzeby aplikacji, przyklejone do tac ociekowych zamontowanych pod sufitem: